In the world of industrial safety, the product you sell, whether it’s a guardrail, a solar rack, or a mezzanine, is built to handle high-stakes pressure.

So why does the process of getting that product to your customer feel so fragile?

If you’ve ever sat at a desk staring at a complex site plan, cross-referencing OSHA handbooks, and manually crunching numbers in a spreadsheet, you know exactly what I’m talking about.

You’re trying to move fast to close a deal, but the Slow Lane of manual quoting is holding you back. One tiny math error or a forgotten baseplate doesn’t just delay the project; it eats your profit margins alive during installation.

The truth is, your customers aren’t just buying steel and fasteners; they’re buying a solution that keeps their people safe and their facility compliant. They want to see it, they want to trust it, and they want to know the price now, not next Tuesday.

In this post, we’re diving into how a modern industrial safety configurator can take your sales cycle from a multi-day headache to a high-speed, automated engine. We’ll look at how to replace static forms with interactive logic, protect your bottom line from The Margin Killer, and use visual tools to show your clients exactly what they’re getting before the first bolt is even turned.

Let’s get your sales team out of the paperwork and back into the field.

Why Manual Quoting Costs Industrial Distributors’ Revenue and Profit Margins

In the traditional industrial sales cycle, the process of generating an accurate quote has become a significant bottleneck that prevents businesses from scaling.

While technology has advanced in almost every other area of industrial operations, the sales desk often remains tethered to legacy methods. This reliance on manual intervention creates a ripple effect of inefficiency that directly attacks a distributor’s financial health through two primary channels: lost momentum and eroded margins.

The Slow Lane: How Delay Kills Sales Momentum

This is the period of dead air that exists between a customer’s request and the delivery of a formal proposal. In many organizations, this process is grueling.

A salesperson must gather site data, manually cross-reference hardware compatibility in bulky catalogs, and often send the requirements to an engineering team for verification. This back-and-forth typically results in a waiting period of three to five days.

In today’s market, speed is a competitive advantage. When a customer has to wait nearly a week for a quote, the initial urgency and sales momentum vanish. This delay does more than just frustrate the client; it opens the door for competitors who can respond faster.

By the time a manual quote is finalized, the customer may have already pivoted to a provider who offered a good enough estimate within twenty-four hours. For the industrial distributor, being stuck in the slow lane means lower conversion rates and a bloated sales cycle that consumes valuable administrative resources.

The Margin Killer: The Hidden Costs of Spreadsheet Error

While the slow lane costs you the sale, the margin killer costs you the profit on the sales you actually win. Manual quoting almost always involves complex spreadsheets where a single human error can have catastrophic financial consequences.

When a salesperson manually calculates linear footage for a guardrail system or counts components for a solar racking kit, the risk of a miscalculation is high. These errors are rarely caught in the office; instead, they are discovered in the field during installation.

The consequences of these inaccuracies are the ultimate margin killers:

- Logistical Nightmares: Realizing you are short on specialized baseplates or rail splices means paying for expedited shipping and emergency manufacturing runs.

- Labor Bleed: Installation crews are often the most expensive part of a project. When a crew is standing idle on a job site because the manual quote missed ten percent of the necessary hardware, the labor costs quickly exceed the projected profit of the job.

- Reputational Damage: Frequent change orders and oops moments during installation damage the trust between a distributor and their contractors, leading to a loss of future recurring revenue.

Manually estimating materials and labor is a significant bottleneck. Providing a way for customers to see how to calculate safety rail costs online instantly builds trust and moves them through the funnel faster than a ‘call for quote’ button ever could.

Shifting the Narrative with Instant Compliance

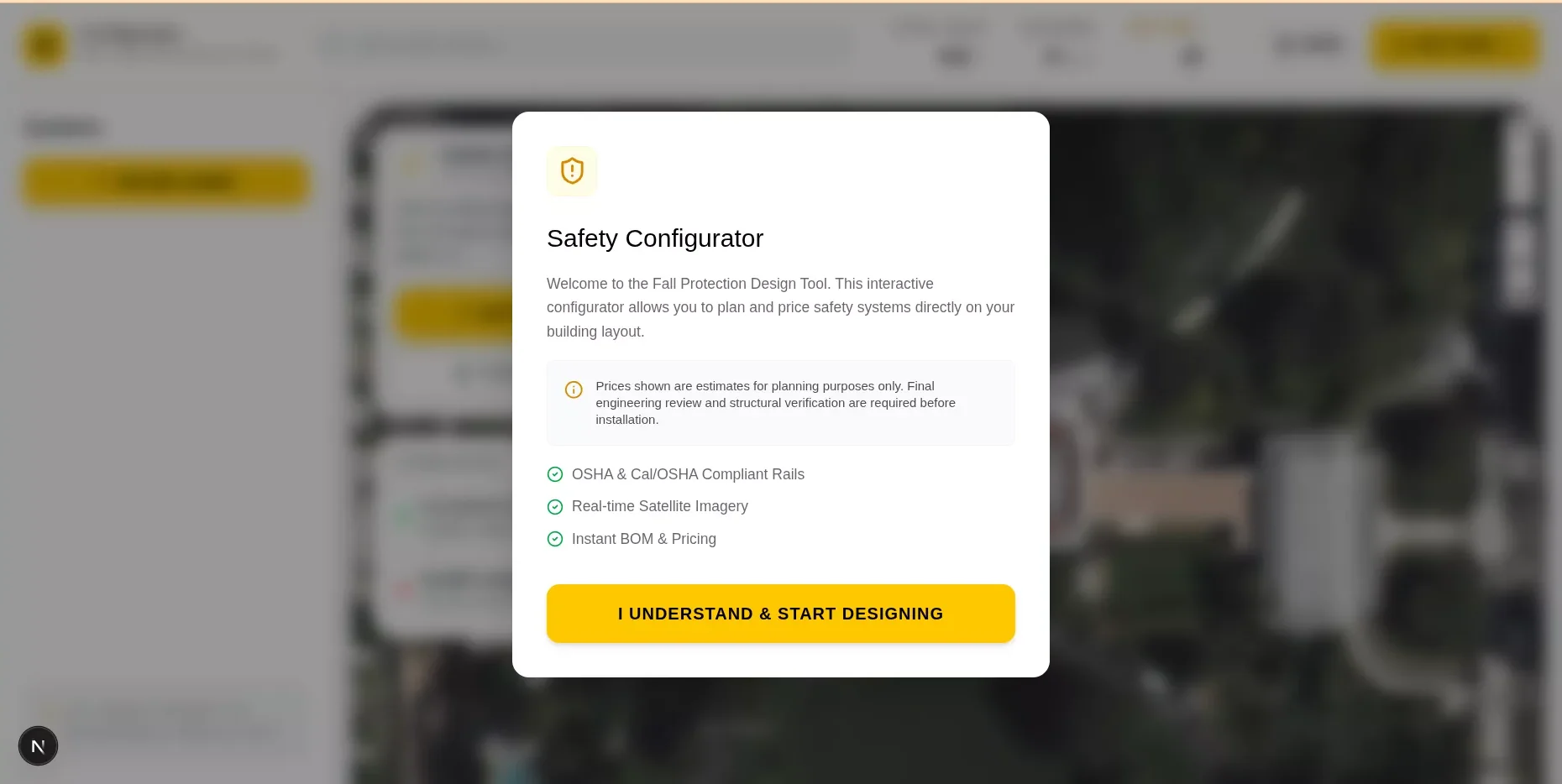

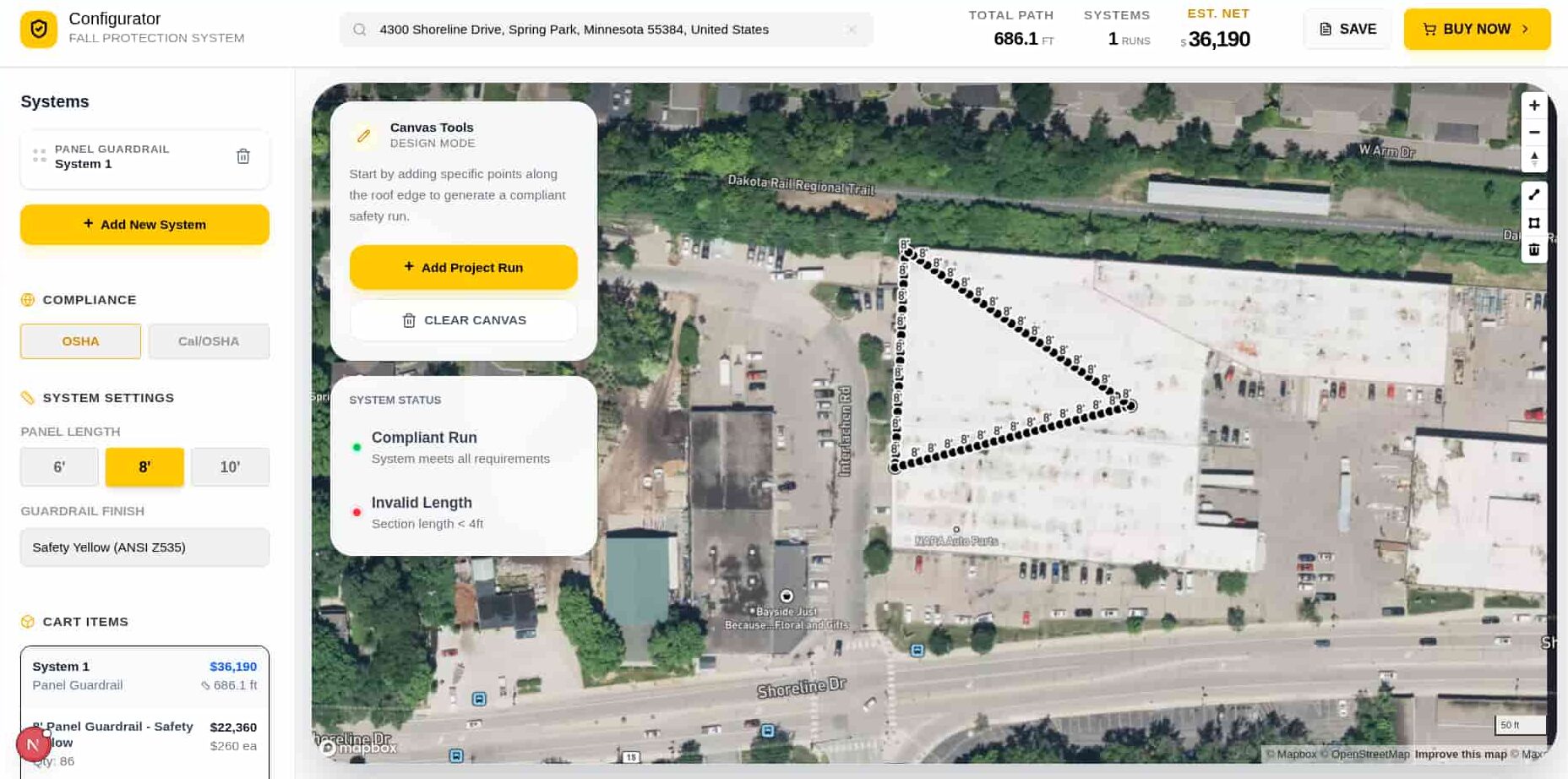

The entry point of the application, emphasizing instant compliance and real-time pricing to solve traditional delays.

The entry point of a modernized sales application changes this dynamic entirely. By moving the logic of the project into a digital configurator, the salesperson is no longer a manual data entry clerk. Instead, they become a high-speed consultant.

The application emphasizes instant compliance and real-time pricing from the first click. This ensures that every quote is mathematically perfect and OSHA-compliant before it ever reaches the customer’s inbox. By solving traditional delays at the point of initialization, distributors can finally exit the slow lane and protect their margins from the volatility of human error.

What is Industrial Safety Configurator and Why Does It Matter?

In the industrial distribution landscape, a configurator is much more than a simple pricing tool.

An industrial safety configurator is a specialized, logic-driven platform that allows users to design, visualize, and price complex safety systems in a virtual environment. It serves as a bridge between high-level safety engineering and the front-end sales process.

By moving away from static catalogs and manual blueprints, this technology enables distributors to create smart designs that understand the physical and regulatory constraints of a real-world job site.

The Shift from Estimation to Precision

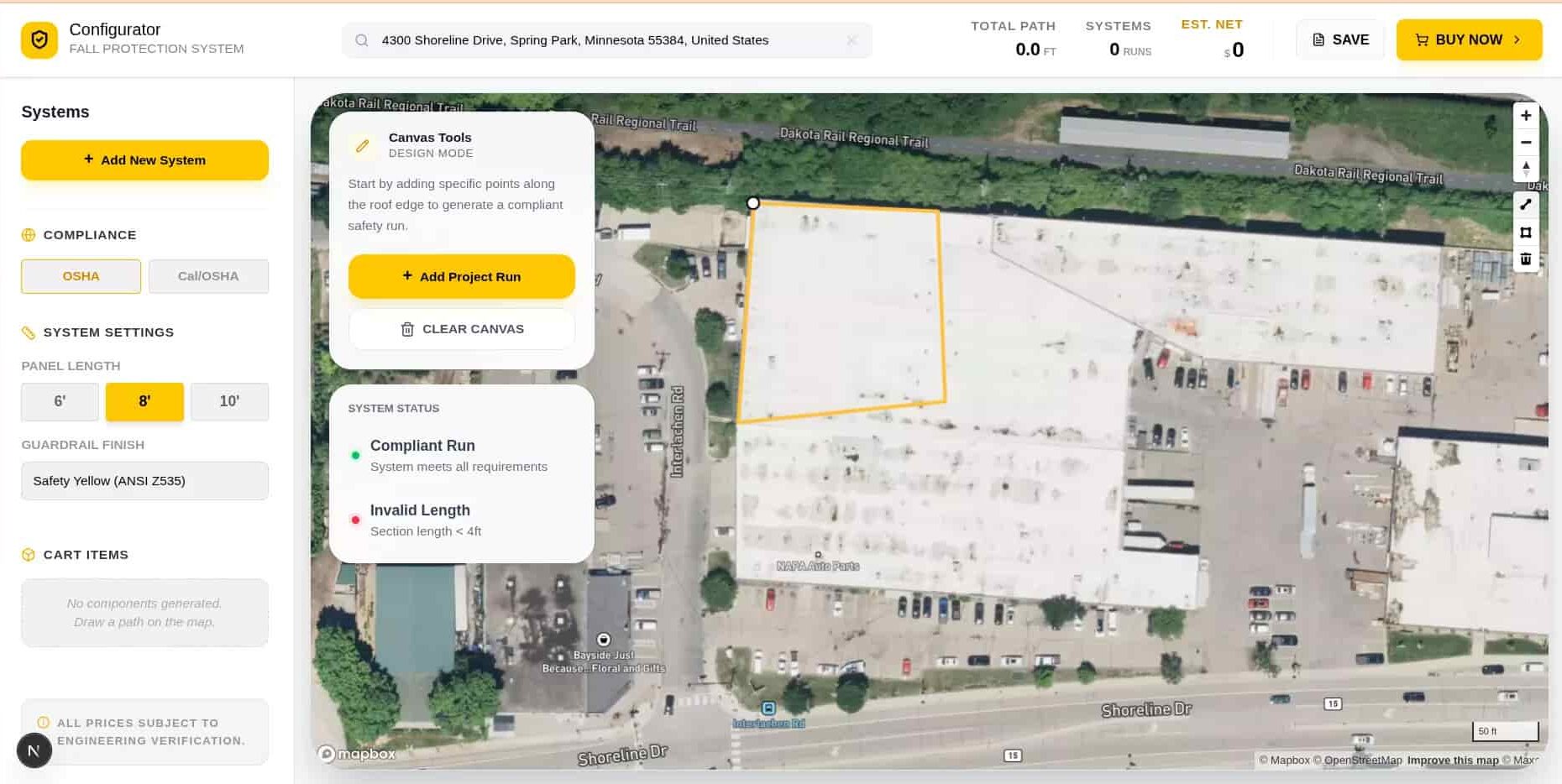

User defined drawing tools that allow for custom perimeter shapes on actual building sites.

For decades, industrial quoting relied on best-guess estimations. A salesperson would look at a blueprint, estimate the number of posts and rails needed, and add a buffer for error. An industrial safety configurator replaces this guesswork with visual logic.

By utilizing 2D satellite layouts and parametric modeling, the software allows a safety system to take shape directly on a digital map of the actual facility. This matters because it provides immediate spatial context: users can see exactly how a guardrail interacts with roof obstructions or how a solar array fits within the available square footage.

This visual clarity eliminates the interpretation gap that often leads to friction between the customer’s expectations and the final delivery.

Why It Matters: The Three Pillars of Value

The adoption of a configurator isn’t just a technical upgrade; it is a strategic business shift. It matters to the modern distributor for three critical reasons:

1. Elimination of the Knowledge Silo: Traditionally, only a handful of senior engineers or specialized estimators knew the intricate spacing rules and hardware compatibility requirements for OSHA-compliant systems.

A configurator democratizes this expertise by embedding those rules into the software itself, allowing any member of the sales team to produce an expert-level design.

2. Financial Transparency Through Live Pricing: In a volatile market, material costs change rapidly. A configurator is linked to a live pricing engine, meaning every design modification, adding a gate, lengthening a run, or changing a finish, instantly updates the Bill of Materials (BOM) and labor estimates.

This real-time feedback allows for live negotiations and faster decision-making.

3. Risk Mitigation via Rule-Based Design: Safety is non-negotiable. The configurator acts as a digital compliance officer, utilizing rule-based design to prevent the creation of any system that violates local building codes or safety standards. This ensures that every quote sent out is not just a price, but a promise of a compliant, legal, and safe installation.

Ultimately, an industrial safety configurator matters because it converts a slow, error-prone administrative task into a high-speed, value-added service. It allows distributors to stop selling parts and start selling verified solutions.

Benefits of Automated Guardrail Quoting for Industrial Distributors

The transition from manual spreadsheets to an automated quoting environment offers more than just incremental speed; it fundamentally reshapes the operational DNA of an industrial distributor.

By automating the most complex variables of the guardrail sales process, businesses can move away from defensive quoting, where margins are padded to cover potential errors, and toward a high-precision model that drives both growth and reliability.

1. Exponential Increase in Sales Capacity

In a manual environment, a sales team’s output is capped by the number of hours they can spend on calculations and CAD drafting. When a quote takes three days to produce, a salesperson can only handle a handful of high-value leads per week.

Automation removes this ceiling. By reducing the time to generate a complex, OSHA-compliant quote from days to minutes, the same sales team can handle five to ten times the volume of inquiries. This allows the organization to pursue smaller, high-margin projects that were previously too expensive to quote, while still maintaining the bandwidth to win major enterprise contracts.

2. Protecting Margins from The Invisible Leak

For many distributors, profit loss isn’t the result of one big mistake, but dozens of small, invisible leaks. These occur when a manual quote forgets a specific fastener, miscounts the baseplates for a corner, or underestimates the freight requirements for heavy industrial steel.

Automated quoting software eliminates these leaks by ensuring every design is backed by an Automated Bill of Materials (BOM).

Because the software understands the kit of parts required for every linear foot of railing, it ensures that every nut, bolt, and post is accounted for. This precision ensures that the profit margin seen on the quote is the actual profit realized at the end of the installation.

3. Shortening the Order-to-Cash Cycle

Cash flow is the lifeblood of industrial distribution. The longer the gap between an initial inquiry and a signed purchase order, the more risk the business carries. Manual quoting stretches this gap, as customers often require multiple revisions that each take days to process.

An automated system allows for live collaborative design. A salesperson can sit with a client (or join a screen share), adjust the layout in real-time on a satellite map, and watch the price update instantly. When the customer can see the design and the final price immediately, they are far more likely to sign the proposal on the spot.

This drastically shortens the sales cycle and gets projects into production faster.

4. Enhancing Brand Authority and Trust

In the safety industry, your brand is built on the confidence you instill in your customers. Providing a client with a hand-written estimate or a generic spreadsheet looks unprofessional and invites skepticism regarding compliance.

Conversely, delivering a professional submittal package that includes a 2D visual layout, a detailed itemized BOM, and a certification of OSHA compliance sets you apart as a market leader.

This level of transparency builds immediate trust with safety managers and facility directors, who are often more concerned with liability and accuracy than the lowest possible price. Workflow automation doesn’t just make you faster; it makes you the most reliable choice in the market.

Key Features of Automated Safety Quoting Tool

To solve the challenges of the slow lane and the margin killer, an automated quoting system must be more than a simple calculator. It requires a suite of integrated tools that handle spatial design, engineering logic, and financial data simultaneously.

The following features represent the core technical foundation of a modern industrial safety configurator.

1. 2D Satellite Mapping & Spatial Integration

The cornerstone of any modern safety design is the ability to work within the context of the actual site. High-resolution 2D satellite mapping allows users to overlay guardrail designs directly onto a building’s footprint.

- Precision Placement: Users can trace roof edges, parapets, and mezzanine perimeters with pinpoint accuracy.

- Contextual Awareness: Being able to see HVAC units, skylights, and existing structural obstacles on a satellite view ensures that the design is viable before a single part is shipped.

- Zero Site Visits: This feature allows sales teams to generate site-accurate quotes from their office, eliminating the travel time and costs associated with manual measurements.

2. Parametric Design Engine

A parametric engine is the brain of the configurator. Unlike standard drawing tools, parametric modeling understands the relationship between parts.

- Dynamic Adjustments: If a user stretches a 20-foot rail run to 30 feet, the engine automatically calculates exactly how many additional posts, midrails, and fasteners are required to maintain structural integrity.

- Smart Offsets: The system can automatically apply required setbacks from roof edges or specify the exact clearance needed for solar racking, ensuring that the design stays within the safe zone defined by the hardware’s specifications.

3. Real-Time Bill of Materials (BOM) Generation

The most critical feature for protecting profit margins is the automated BOM. In a manual workflow, the BOM is often the last thing created and the most likely to contain errors.

- Instant Itemization: As the design takes shape on the canvas, the software builds an itemized list of every component in the background.

- Hardware Logic: The system knows that a corner requires a different post than a run, and it automatically swaps out parts based on the layout geometry.

- Freight & Weight Calculation: By knowing the exact weight of the total BOM, the system can provide more accurate shipping estimates, preventing unexpected logistics costs from eating into the project’s profit.

4. Integrated OSHA Compliance Logic

In the safety industry, a design that isn’t compliant is a liability. Automated software incorporates a rule-based design to act as a digital safety consultant.

- Automated Guardrails: The system enforces standard height requirements (typically 42 inches per OSHA 1910.29) and prevents post spacing that exceeds safety limits.

- Error Flagging: If a user attempts to create a configuration that is structurally unsound or non-compliant, the system alerts them immediately, preventing the quote from being sent until the issue is resolved.

5. Instant Submittal & Proposal Generation

The final step in modernizing the sales cycle is the professional output. Once the design is finished, the software can instantly generate a comprehensive proposal package.

- Visual Reports: Proposals include the 2D satellite layout, providing the customer with clear visual proof of the project scope.

- Technical Data Sheets: Automatically attach hardware specs and compliance certifications, giving the client’s engineering or safety team everything they need to approve the purchase quickly.

Caption: The interactive canvas interface where 2D mapping and parametric logic combine to create a perfect, quote-ready design in minutes.

Together, these features transform guardrail quoting from a slow, error-prone task into a streamlined, reliable process that supports scalable growth for industrial distributors.

An Overview of Bitcot’s Solution for Automated Guardrail Quoting

Our application is a dynamic design engine that replaces static Contact Us forms with interactive logic.

In an industry where speed and precision are paramount, Bitcot moves beyond passive data collection to provide a high-performance environment where safety systems are engineered in real time. By embedding technical expertise directly into the interface, we empower distributors to deliver expert-level results without the traditional overhead of manual engineering.

This transition to self-service safety design democratizes expertise by embedding complex rules into the software, allowing any team member to produce an expert-level, compliant design.

A Seamless Workflow: From Selection to Design

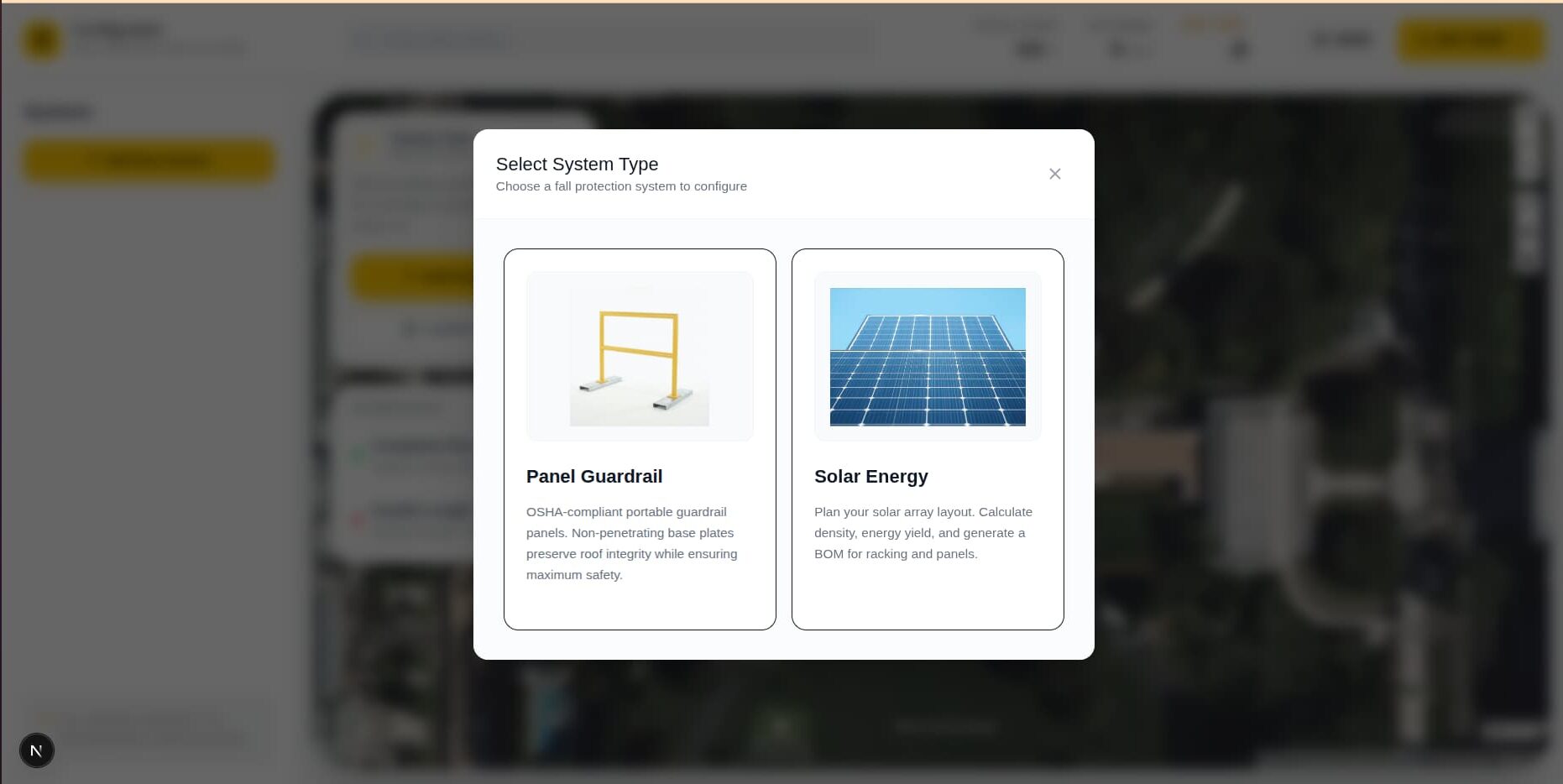

The Selection Interface. Choosing a system type here dynamically loads the specific engineering rules and pricing for the drawing phase.

One of the core strengths of the configurator is its intuitive user journey. The application guides the user through a logical progression that ensures the correct hardware is selected before any design work begins. This guardrail for the sales process ensures that every project starts on a foundation of technical accuracy.

- Product Initialization: The process starts with the Select System Type interface. This ensures the user chooses the specific hardware, such as OSHA-compliant Panel Guardrails, that fits their structural needs. By establishing the system type first, the software can load the corresponding engineering constraints and material costs immediately.

- Activating the Canvas: Once the system type is confirmed, the application automatically unlocks the Canvas Tools. This intelligent transition ensures the user has exactly the right toolset for the chosen hardware, eliminating the clutter of irrelevant options.

- Transition to Drawing: This hand-off allows the user to immediately begin placing points on the satellite map, with the system already knowing the technical specifications and pricing of the selected hardware. The drawing phase is not just a sketch; it is a data-rich engineering model.

Caption: The Selection Interface. Choosing a system type here dynamically loads the specific engineering rules and pricing for the drawing phase.

Tech Stack for the Automated Logic Layer

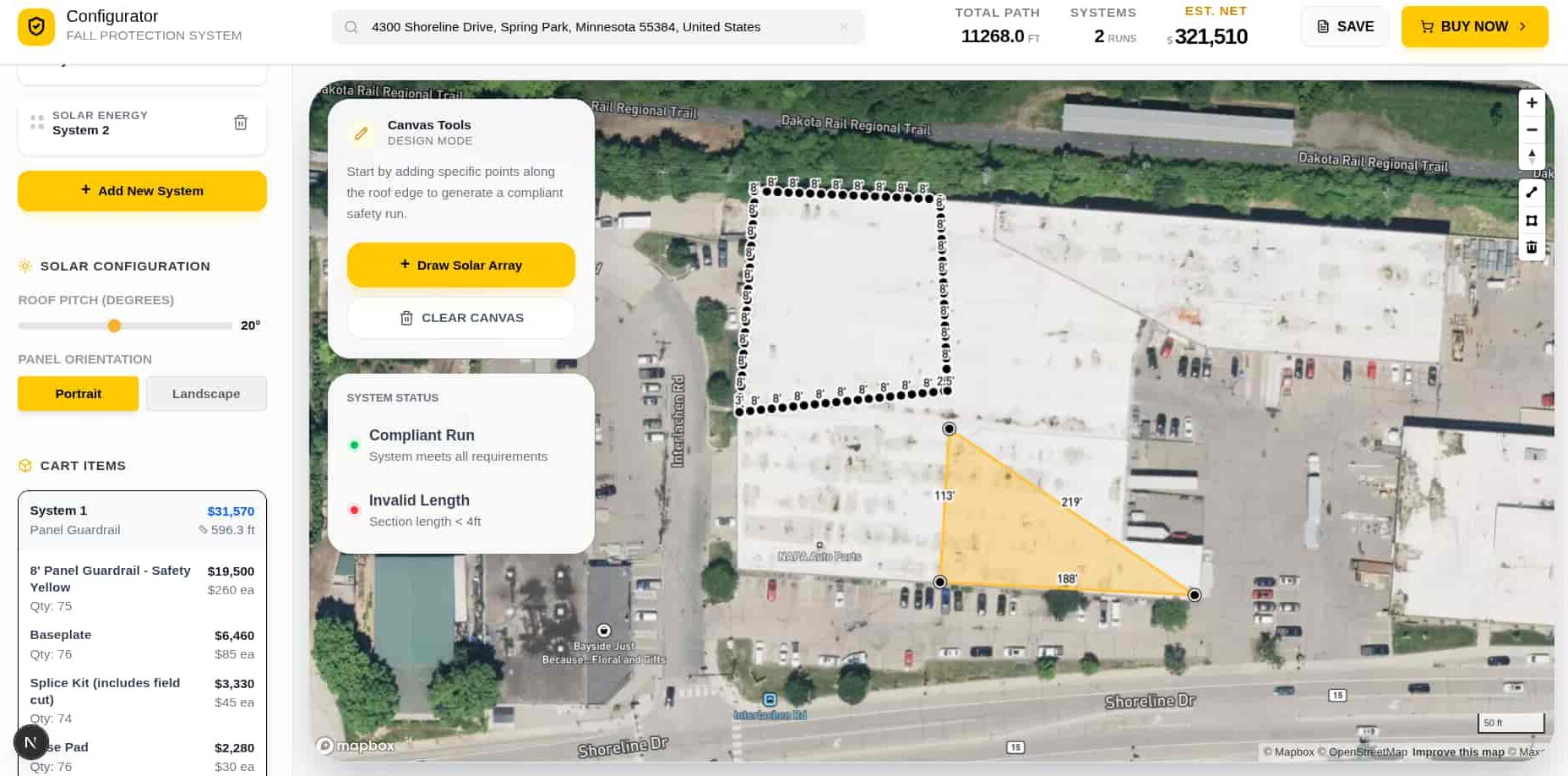

Detailed breakdown of a 1011.5 ft guardrail run showing automated component counting and a $46,990 total price.

The power of the configurator lies in its automated logic layer. This digital brain works silently in the background, handling the complex calculations that typically cause bottlenecks in the manual sales cycle.

- Parametric Modeling: The engine utilizes advanced parametric modeling. As a user extends a railing, the system automatically increases the number of posts and baseplates required to maintain structural integrity.

- Dynamic BOM Generation: The application creates a granular list of every component needed for the project. This Dynamic BOM Generation tracks everything from primary rails to the smallest fasteners, ensuring that nothing is missed and profit margins are protected.

The integrated real-time BOM generator tracks everything from primary rails to the smallest fasteners as the design takes shape, ensuring that nothing is missed and profit margins are protected.

- Compliance Validation: Safety is at the heart of the design. Real-time feedback tells the user if their run is Compliant or Invalid based on length and OSHA spacing rules.

Visual Logic and Real-Time Feedback

By integrating visual logic, our application allows users to see the safety rail or solar array take shape directly on a 2D satellite layout of an actual building site. This spatial context is paired with a Live Pricing Engine; every modification to the design triggers an instant update in the material costs and labor estimates.

Ultimately, this rule-based design approach prevents users from designing systems that violate OSHA or local building codes.

By combining user-defined drawing tools that allow for custom perimeter shapes on actual building sites with automated compliance, Bitcot’s solution ensures that the transition from a design on a screen to a physical installation is seamless, accurate, and safe.

How to Modernize the Sales Cycle with an OSHA Guardrail Configurator

To modernize your sales cycle using an OSHA-grade guardrail software, you need a clear, repeatable roadmap.

This step-by-step guide outlines how to transition your sales team from a legacy slow lane workflow to a high-velocity, digital-first operation.

Step 1: Digitize the Site Survey with Satellite Integration

The first step in modernization is eliminating the need for immediate, manual site visits.

- The Action: Instead of dispatching a team to measure a roof with tape measures, use the software’s 2D Satellite Mapping.

- The Result: By pulling high-resolution imagery of the actual building site, your sales team can begin the discovery phase remotely. This allows you to provide a Rough Order of Magnitude (ROM) quote within minutes of the initial lead coming in.

By utilizing a satellite-based roof safety planner, sales teams can generate site-accurate quotes directly from their office, eliminating the travel time and costs associated with manual measurements.

Step 2: Initialize the Compliance Engine

Before a single line is drawn, you must lock in the safety parameters.

- The Action: Use the Product Initialization interface to select the specific hardware (e.g., Non-Penetrating Guardrails).

- The Result: This activates the OSHA 1910.29 compliant rail designer logic layer. By selecting the system type first, the software automatically loads the correct post-spacing rules, height requirements, and load-bearing specs. This ensures that the salesperson cannot accidentally design a non-compliant system.

When a user selects specific hardware in the non-penetrating guardrail calculator, the system automatically loads the corresponding engineering constraints, such as required setbacks and load-bearing specs.

Step 3: Rapid Prototyping via Visual Logic

Once the hardware is set, move to the interactive canvas to build the solution in real-time.

- The Action: Trace the perimeter of the hazard (roof edge, skylight, or mezzanine). As you draw, the parametric modeling engine will automatically populate the posts and rails.

- The Result: This provides immediate visual logic. The customer can see the safety system take shape on their building. If they want to move a gate or add a corner, you do it instantly on-screen, rather than waiting for a CAD revision.

Step 4: Synchronize Pricing and Compliance Validation

As the design evolves, the financial and legal data must keep pace.

- The Action: Monitor the Live Pricing Engine and Compliance Validation flags.

- The Result: If the design exceeds a safe span, the system flags it as Invalid. Simultaneously, the Dynamic BOM Generation updates the material costs and labor estimates. This means the salesperson is always looking at a final, profitable, and compliant number, never a guestimate.

Step 5: Instant Proposal and Submittal Generation

The final step is to move from Design to Contract without leaving the meeting.

- The Action: Click Generate Proposal to produce a professional submittal package.

- The Result: This package includes the 2D layout, the itemized Bill of Materials, and the safety certification. By delivering a board-ready document instantly, you eliminate the 3-5 day waiting period typical of the slow lane, allowing the customer to sign and approve on the spot.

By following this five-step guide, industrial distributors can transform their sales department into a high-efficiency engine that protects margins and closes deals with total confidence.

Real-World Use Cases of Automated Guardrail Quoting Software

The true strength of an OSHA-grade configurator lies in its versatility. While the slow lane is a universal problem, every industry has unique technical hurdles.

By utilizing sector-specific use cases, we can see how the software adapts its rule-based design to meet the distinct demands of different industrial environments.

1. Rooftop Safety & Guardrails

In the world of fall protection, the margin for error is zero. When designing safety rails for a complex roof, the software focuses on the geometry of the perimeter.

- The Workflow: Using 2D Satellite Mapping, the user identifies roof edges and obstacles.

- The Logic: The system ensures all rails meet the mandatory 42-inch height and that corner angles are reinforced correctly based on the selected mounting type (e.g., non-penetrating vs. bolt-down).

- The Outcome: The salesperson provides a quote that is pre-certified for OSHA compliance, eliminating the risk of a safety inspector rejecting the installation later.

2. Solar Energy Infrastructure

Solar projects are high-density and hardware-intensive. Here, the configurator shifts its focus to spatial optimization and material precision.

- The Workflow: The user defines the total square footage and the roof pitch.

- The Logic: The Parametric Modeling engine calculates the ideal panel density and determines the exact racking hardware needed to support the load.

- The Outcome: Because the Dynamic BOM Generation is so precise, the project avoids the margin killer of under-ordering specialized solar fasteners or rail splices, ensuring accurate energy yield projections from day one.

3. Industrial Mezzanines & Internal Guarding

Internal warehouse platforms require heavy-duty engineering logic to ensure worker safety on elevated levels.

- The Workflow: The user maps out the mezzanine floor plan, including required access points.

- The Logic: The software focuses on load-bearing specs and the critical placement of stairways and swing gates. It automatically adjusts post spacing to ensure the structure can withstand the required force impacts.

- The Outcome: By validating the design during the initial walkthrough, the distributor drastically reduces engineering back-and-forth. What used to take weeks of CAD revisions is now a finished, approved design before the salesperson leaves the facility.

To illustrate how this tool functions across various scenarios, the following table breaks down the focus and primary advantages for key sectors:

| Industry | Configurator Focus | Key Benefit |

| Safety Rails | Compliance with heights, corner angles, and mounting types. | Instant OSHA compliance verification and structural integrity checks. |

| Solar Energy | Roof pitch, panel density, and racking hardware. | Accurate energy yield projections and a precise Bill of Materials (BOM). |

| Industrial Mezzanines | Load-bearing specs and stair placement. | Reduces engineering back-and-forth by validating designs in real-time. |

Partner with Bitcot to Build Your Custom Industrial Fall Protection Software

Modernizing your sales process is a significant undertaking, but you don’t have to build the bridge alone.

As industrial distribution shifts toward a digital-first model, the competitive advantage belongs to those who can provide instant compliance and real-time accuracy. At Bitcot, we specialize in transforming complex engineering slow lanes into high-velocity, automated sales engines.

Why Choose Bitcot for Your Industrial Software?

We understand that an industrial safety configurator is more than just a website; it is a mission-critical tool that must handle millions of dollars in liability and materials.

Our team brings the technical depth required to build systems that are as robust as the hardware you sell.

- Custom Logic Integration: We don’t believe in one-size-fits-all. We work with your engineering team to hard-code your specific product rules, ensuring the rule-based design reflects your unique catalog and OSHA-grade standards.

- Scalable Cloud Architecture: Our solutions are built on a future-proof tech stack, ensuring that as your product line grows from guardrails to solar racking or mezzanines, your software scales with you without performance lag.

- User-Centric Design: We focus on the intuitive user journey. We build interfaces that empower your sales team, not confuse them, ensuring high adoption rates and immediate ROI.

- AI Chatbot & CRM Integration: Our configurators can integrate with AI-powered chatbots and CRM systems, capturing lead requirements automatically and passing structured inputs directly into the configurator for instant, accurate quote generation.

Turn Your Margin Killer into a Competitive Edge

Every day your team spends manually calculating linear footage in a spreadsheet is a day of lost revenue and potential error.

By partnering with Bitcot, you are investing in a solution that:

- Eliminates Quoting Bottlenecks by providing instant, professional submittals.

- Protects Your Bottom Line through Dynamic BOM Generation that accounts for every nut and bolt.

- Enhances Brand Trust by providing customers with Visual Logic and 2D satellite layouts that prove your expertise.

By partnering with Bitcot, you move beyond manual spreadsheets and static PDFs to a dynamic, automated configurator that improves accuracy, accelerates sales cycles, and strengthens compliance.

Final Thoughts

Let’s be honest: in the industrial world, software isn’t usually the first thing people think of when they talk about safety.

We think about high-grade steel, heavy-duty baseplates, and the peace of mind that comes with a job done right. But as we’ve seen, the most dangerous part of a project isn’t always the heights; it’s the slow lane.

When your sales team is buried in spreadsheets, and your customers are waiting days for a price, you aren’t just losing time; you’re losing the trust and momentum that drive your business forward.

Modernizing your sales cycle isn’t about chasing a trend. It’s about making sure that the expertise your team has in their heads is reflected instantly on the screen. It’s about ensuring that the margin killer doesn’t stand a chance against a perfectly calculated, automated Bill of Materials.

By moving to an OSHA-grade configurator, you’re telling your clients that you value their time and their safety equally. You’re shifting from being a vendor who sells parts to a partner who provides verified, visual solutions.

The jump from manual quoting to a high-velocity digital engine is a big one, but it’s the most profitable move an industrial distributor can make in 2026. You provide the safety expertise; we provide the digital architecture to bring it to life.

If you’re ready to reclaim your margins and exit the slow lane, Bitcot is here to help. Our custom software development services are designed specifically to handle the complex, rule-based logic that industrial businesses require.

Let’s build a solution that works as hard as your hardware does.

Ready to modernize your sales cycle?

Don’t let your sales team stay stuck in the Slow Lane. Let’s build a tool that makes your quoting process as safe and reliable as the products you manufacture.

Get in touch with us!