Order management is one of the most critical pillars of supply chain operations because it touches almost every stage of the fulfillment lifecycle.

It’s not just about placing or receiving orders; it involves checking inventory levels to prevent stockouts, coordinating with procurement teams, routing approvals through the right decision-makers, and ensuring timely fulfillment and delivery.

When these steps are handled efficiently, the supply chain flows seamlessly.

But when they rely on manual processes, delays, miscommunication, and errors start to creep in, impacting both operational performance and customer satisfaction.

As businesses grow and order volumes increase, managing these processes through spreadsheets, emails, and disconnected systems becomes unsustainable. Approvals get stuck in inboxes, procurement cycles slow down, fulfillment teams miss critical updates, and inventory visibility becomes fragmented.

That’s exactly where automation with Power Automate makes a difference, by connecting systems, streamlining workflows, and eliminating the repetitive tasks that slow teams down.

In this blog, we’ll look at how you can automate supply chain order management using Power Automate to accelerate fulfillment, improve accuracy, and keep every stakeholder, from procurement to logistics, on the same page.

Challenges in Traditional Supply Chain Order Management

Let’s face it: relying on legacy systems and manual processes for supply chain order management feels like bringing a paper map to a GPS world.

Let’s face it: relying on legacy systems and manual processes for supply chain order management feels like bringing a paper map to a GPS world.

These outdated methods are more than just slow; they’re actively creating friction.

From pervasive inventory errors that frustrate sales teams to slow fulfillment times that annoy customers, the core challenges of traditional systems are directly impacting your bottom line and your competitive edge. It’s time to examine the most painful, costly bottlenecks.

Here’s a closer look at the common pain points:

- Manual Entry Delays: Many organizations still rely on re-keying order details from emails, portals, or purchase requests into ERP or inventory systems. This repetitive process is not only time-consuming but also prone to human error. A single mistyped order quantity or incorrect SKU can delay procurement and fulfillment, creating bottlenecks across the supply chain.

- Inventory Mismatches: Without real-time inventory tracking, stock data often becomes outdated. This can lead to situations where orders are processed for items that are out of stock, resulting in backorders, delayed shipments, and frustrated customers. The lack of accurate inventory visibility also makes it difficult for procurement teams to plan purchases effectively.

- Slow Approvals: Many organizations require multiple levels of approval for purchase orders, especially for high-value or critical items. When these approvals are routed manually via email or paper forms, decision-making slows down considerably. Delayed approvals not only extend lead times but also increase the risk of missing delivery deadlines.

- Limited Visibility Across Systems: Traditional workflows often span multiple disconnected platforms: ERP, CRM, inventory databases, and communication tools. Teams struggle to track the status of orders in real-time, leading to miscommunication, duplicate efforts, and a reactive rather than proactive approach to managing supply chain issues.

These challenges add up to slower fulfillment, increased operational costs, and reduced customer satisfaction. Organizations need a more streamlined, automated approach to manage orders efficiently and gain full visibility across the supply chain.

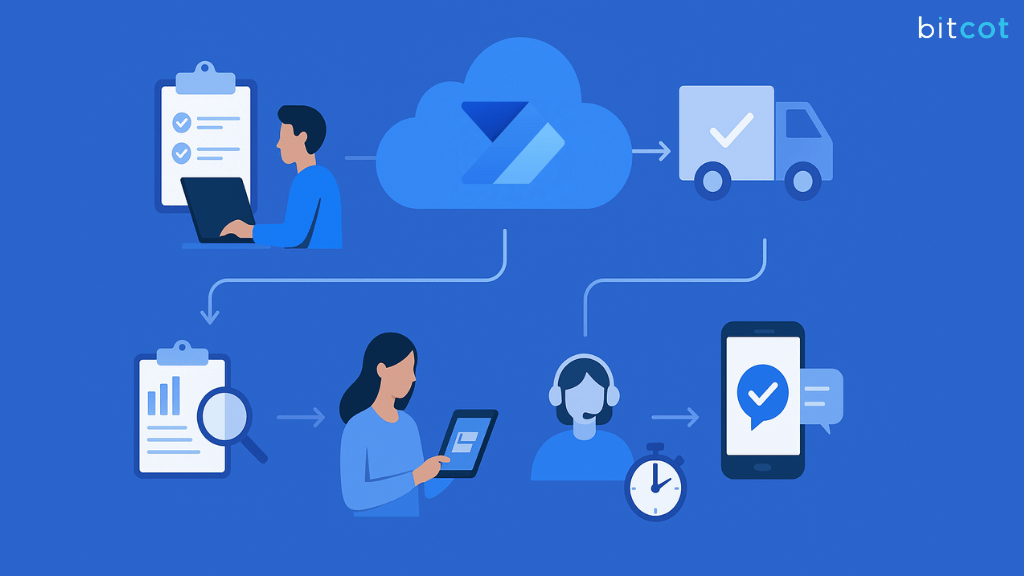

How Power Automate Transforms Supply Chain Order Management

Power Automate revolutionizes supply chain order management by integrating systems, automating approvals, and leveraging AI.

Power Automate revolutionizes supply chain order management by integrating systems, automating approvals, and leveraging AI.

This transformation ensures orders are processed faster, accurately, and with full visibility, allowing teams to focus on strategic tasks rather than repetitive manual work.

1. Automated Intake of Purchase Orders

Orders often arrive from multiple sources, including emails, supplier portals, or internal request forms. Traditionally, each order must be manually entered into ERP or inventory systems, which is time-consuming and prone to errors.

Power Automate centralizes all incoming orders automatically, standardizing data and storing it in platforms like Dataverse or SharePoint. By eliminating manual entry, organizations save time, reduce mistakes, and ensure that no order is missed, enabling supply chain teams to process requests efficiently and without delays.

2. Real-Time Inventory and Procurement Validation

Once orders are captured, verifying inventory and procurement requirements is critical. Power Automate integrates with ERP and inventory systems to check stock availability, validate supplier lead times, and ensure compliance with internal procurement rules. If an order cannot be fulfilled immediately, the workflow flags it for backordering or alternative sourcing.

This automated validation prevents errors, reduces fulfillment delays, and guarantees that only feasible orders move forward. Teams gain confidence that every order in the system is accurate and actionable.

3. Smart Routing and Approval Workflows

Many supply chains require multi-level approvals, which can cause significant delays if handled manually. Power Automate automatically routes orders to the right managers or departments based on predefined rules. Notifications via Teams or email allow approvers to review and act promptly, while escalation paths prevent approvals from being stuck.

By automating this process, organizations accelerate decision-making, maintain continuous workflow, and avoid bottlenecks, ensuring that orders progress efficiently from request to fulfillment without unnecessary manual follow-ups.

4. Automatic ERP and Inventory Updates

After orders are approved, updating multiple systems manually can be time-intensive and error-prone. Power Automate synchronizes ERP, inventory, and procurement platforms automatically, ensuring consistent, accurate data across all systems. This eliminates reconciliation work, reduces duplicate entries, and gives teams access to reliable, real-time information.

With automated updates, supply chain teams can plan production, allocate resources, and manage shipments confidently, resulting in smoother operations and faster fulfillment cycles without depending on manual intervention.

5. Real-Time Visibility and Alerts

Tracking orders across multiple systems is often a major challenge. Power Automate feeds workflow data into dashboards and triggers real-time alerts for critical events, such as stock shortages, delayed approvals, or processing exceptions. Supply chain managers can monitor the status of every order, respond proactively to issues, and coordinate teams more effectively.

By providing visibility across the entire order lifecycle, automation enables faster decision-making, improves fulfillment speed, and ensures that supply chain operations remain transparent and agile under increasing demand.

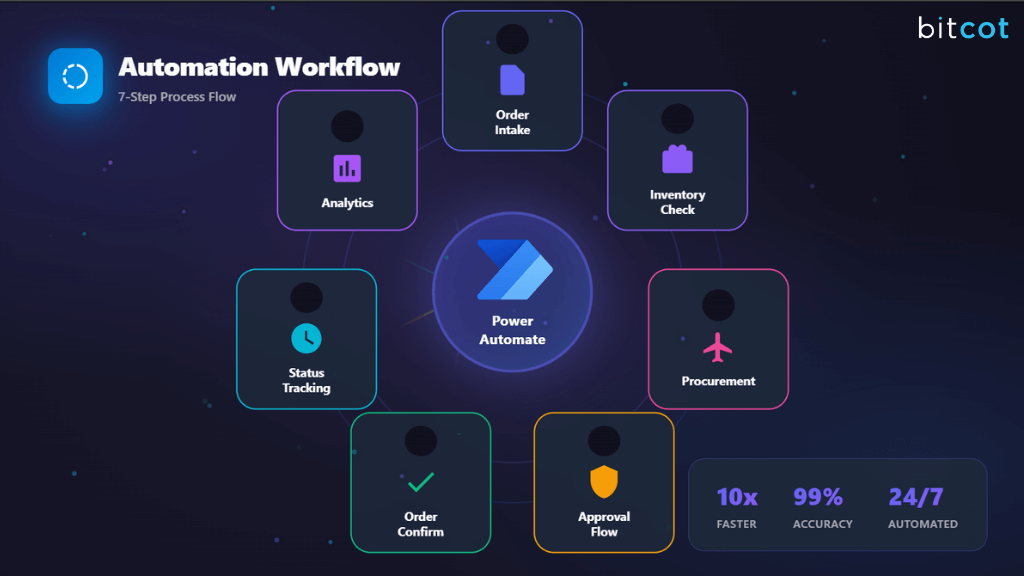

How to Automate Supply Chain Order Management with Power Automate

Automating supply chain order management with Power Automate streamlines the entire process from order intake to fulfillment and reporting.

Automating supply chain order management with Power Automate streamlines the entire process from order intake to fulfillment and reporting.

By connecting multiple sources, validating inventory, automating approvals, and updating systems in real-time, businesses can reduce manual work, prevent errors, and improve visibility across the supply chain.

Here’s a step-by-step guide:

Step 1: Order Intake & Preprocessing

Orders can arrive from multiple sources, including:

- Customer portals

- Partner systems (via API/EDI)

- Email attachments

Power Automate Actions:

- When a new response is submitted: Capture portal order forms automatically.

- When a new email arrives (V3): Process emailed orders seamlessly.

- Get file content: Retrieve purchase order files such as PDFs or Excel sheets.

- Extract information from documents: Use AI Builder Form Processing to capture critical order details like item, quantity, and price.

By automating order intake, businesses eliminate repetitive data entry, reduce human error, and ensure that all orders are accurately captured in the system, ready for the next steps.

Step 2: Inventory Check & Availability Validation

Before confirming an order, it’s essential to ensure that stock is available and ready for fulfillment.

Power Automate Actions:

- SQL Server – Get rows: Query the inventory database for real-time stock levels.

- Filter array: Match ordered items against available inventory.

- Condition: If items are unavailable, trigger a procurement workflow automatically.

Best Practice: Maintain a real-time inventory feed to prevent stock-outs and reduce order delays. This ensures customers are not promised items that aren’t available and helps procurement teams plan effectively.

Step 3: Procurement & Supplier Engagement

When items are not available in inventory, procurement must be initiated promptly to avoid delays.

Power Automate Actions:

- Create item: Log procurement requests in SharePoint or Dataverse for tracking.

- Send an email (V2): Notify suppliers about the purchase requirement.

- HTTP: Connect to supplier APIs to submit purchase requests automatically.

Automating procurement reduces delays, ensures timely replenishment of stock, and improves collaboration with suppliers without relying on manual intervention.

Step 4: Approval Workflow (if required)

Some orders, particularly high-value or sensitive ones, may require managerial approval.

Power Automate Actions:

- Start and wait for an approval: Request authorization from the appropriate manager.

- Post adaptive card and wait for a response: Provide order details within Microsoft Teams for fast decision-making.

- Condition: If rejected, notify the sales or order management team automatically.

This ensures approvals are handled quickly and transparently, preventing bottlenecks while maintaining compliance and governance standards.

Step 5: Order Confirmation & Fulfillment

Approved orders need to be confirmed and sent to fulfillment systems for processing.

Power Automate Actions:

- HTTP: Update ERP or order management systems via API with the approved order details.

- Update item: Record the confirmed order in SharePoint or Dataverse tracking lists.

- Send an email (V2): Notify the customer about order confirmation and expected delivery.

Automation in this step reduces errors in order entry, ensures that fulfillment teams have accurate data, and provides customers with timely updates.

Step 6: Status Notifications & Tracking

Keeping all stakeholders updated on order progress is critical for operational efficiency.

Power Automate Actions:

- Send push notification: Alert warehouse staff about orders ready for fulfillment.

- Post message in a chat or channel: Update sales and logistics teams in Microsoft Teams.

- Update item: Maintain a comprehensive status log for each order.

Real-time notifications and tracking help avoid missed shipments, improve coordination across departments, and enable proactive handling of exceptions.

Step 7: Reporting & Analytics

Finally, tracking and analyzing orders is essential to optimize supply chain performance.

Power Automate Actions:

- Add a row into a table: Store order history in Excel or Dataverse for future analysis.

- Refresh a dataset: Update Power BI dashboards to reflect real-time performance metrics.

- Create HTML table: Generate weekly or monthly summary reports automatically for management review.

With automated reporting, organizations gain insights into order cycles, fulfillment accuracy, and bottlenecks, enabling continuous improvement and data-driven decision-making.

Benefits of Automating Supply Chain Order Management with Power Automate

Automating supply chain order management with Power Automate delivers measurable advantages across every stage of the workflow.

Automating supply chain order management with Power Automate delivers measurable advantages across every stage of the workflow.

From intake to fulfillment and reporting, automation streamlines operations, improves accuracy, and enables better decision-making.

Here are the key benefits:

Faster Order Processing

Manual order entry, approval delays, and scattered data sources can slow down supply chain operations. Power Automate captures orders automatically from multiple sources, validates them, and routes them for approvals in real-time.

This reduces the time spent on repetitive tasks and accelerates the entire order lifecycle. Organizations can process more orders in less time, meet customer expectations faster, and ensure that the supply chain keeps moving efficiently without unnecessary delays.

Accurate Inventory Management

Stock mismatches and delayed updates can cause order errors and fulfillment issues. Power Automate integrates with inventory and ERP systems to perform real-time stock checks and availability validations. By ensuring that every order is backed by accurate inventory data, businesses can minimize errors, prevent stock-outs, and reduce manual reconciliation efforts.

Accurate inventory management also allows supply chain teams to make informed decisions about procurement and resource allocation.

Improved Supplier Collaboration

Procurement delays often occur when inventory is unavailable or supplier requests are handled manually. Automation allows organizations to trigger procurement workflows instantly, notify suppliers via email, and even connect directly with supplier APIs.

This reduces delays, improves response times, and ensures timely replenishment of stock. Automated supplier collaboration also helps maintain stronger relationships by keeping suppliers informed and engaged throughout the procurement process.

Enhanced Customer Experience

Customers expect timely order confirmations and real-time updates on their purchases. Power Automate ensures that once an order is approved, confirmations are sent automatically, and fulfillment teams are notified immediately.

Real-time status notifications and tracking allow customers to stay informed, reducing uncertainty and improving satisfaction. By streamlining communication and providing consistent updates, businesses can deliver a seamless customer experience that builds trust and loyalty.

Data-Driven Decisions

Supply chain teams often lack visibility into order bottlenecks, processing delays, or fulfillment trends. Automation feeds workflow data into dashboards and reporting tools like Power BI, providing insights into performance metrics, cycle times, and operational bottlenecks.

These insights allow managers to identify areas for improvement, optimize workflows, and make informed, proactive decisions. Data-driven visibility helps businesses continuously refine processes, improve efficiency, and scale operations effectively.

Future Enhancements in Supply Chain Order Management Automation

While Power Automate already streamlines order management, future enhancements can take supply chain efficiency to the next level.

While Power Automate already streamlines order management, future enhancements can take supply chain efficiency to the next level.

By integrating advanced technologies and smarter automation, businesses can further reduce manual work, improve accuracy, and enhance customer experience.

Here are the key areas for future improvement:

1. Integration with Predictive Demand Forecasting

Traditional order management relies on historical data, which may not anticipate sudden demand spikes or seasonal trends. By integrating predictive demand forecasting models into Power Automate workflows, businesses can anticipate inventory requirements, optimize procurement, and prevent stock-outs.

Automated alerts based on forecasted demand can trigger early procurement or production adjustments, ensuring the right products are available at the right time and reducing reactive decision-making.

2. Chatbot Integration for Customer Order Status

Customers increasingly expect instant updates on their orders without having to call support. Future automation can include AI chatbot integration, allowing customers to check order status, expected delivery, and shipment details directly through websites, apps, or messaging platforms.

By connecting AI chatbots to Power Automate workflows, businesses can provide real-time, self-service updates, reduce customer support workload, and enhance satisfaction with faster, personalized communication.

3. RPA Connectors for Legacy ERP Systems

Many supply chains still rely on legacy ERP systems without modern APIs, making automation challenging. Robotic Process Automation (RPA) connectors can bridge this gap, allowing Power Automate to interact with older systems through screen scraping or automated data entry.

This capability ensures that organizations can automate workflows end-to-end, even when critical systems are outdated, improving efficiency and reducing reliance on manual operations.

4. Automated Invoice Generation and Payment Tracking

Order management doesn’t end with fulfillment; managing invoices and payments is equally critical. Future automation can generate invoices automatically once orders are confirmed, send them to customers, and track payment statuses.

By connecting payment gateways and accounting systems with Power Automate, businesses can streamline financial operations, reduce errors, and ensure that revenue recognition and cash flow tracking happen seamlessly alongside order fulfillment.

Partner with Bitcot to Automate Supply Chain Order Management with a Custom Solution

Selecting the right partner is critical when automating complex supply chain workflows.

Selecting the right partner is critical when automating complex supply chain workflows.

Bitcot stands out because we combine deep technical expertise with a strong focus on business outcomes, ensuring organizations achieve measurable improvements in efficiency, accuracy, and scalability.

Here’s why businesses consistently choose Bitcot to build custom Power Automate solutions:

- Proven Expertise Across Industries: With years of experience in automating business processes, Bitcot has successfully delivered complex solutions for clients across manufacturing, retail, logistics, and more. Our expertise ensures your supply chain workflows are optimized from day one, minimizing errors and maximizing throughput.

- Reliable and Secure Solutions: Businesses trust Bitcot to implement robust automation that is secure, compliant, and resilient. We follow best practices in data security and system reliability, ensuring your critical supply chain data is protected while workflows run smoothly.

- Results-Focused Approach: Our priority is delivering measurable outcomes, not just technology. From faster order processing and improved inventory accuracy to reduced operational costs and actionable insights, Bitcot ensures that every automation initiative produces tangible business value.

- Adaptable and Scalable Automation: As your business grows, so do your supply chain requirements. Bitcot designs solutions that scale seamlessly, accommodating increased order volumes, expanding supplier networks, and evolving operational processes without compromising performance.

- Commitment to Continuous Improvement: We don’t just implement automation and walk away. Bitcot provides ongoing monitoring, workflow optimization, and proactive support, ensuring your automation adapts to changing business needs and continues to deliver value over time.

- Client-Centric Partnership: Bitcot’s approach is deeply collaborative. We take the time to understand your unique business challenges, goals, and operational nuances. This allows us to craft solutions that are not only technically sound but also strategically aligned with your long-term objectives.

- Driving Strategic Advantage: Beyond operational efficiency, Bitcot helps you leverage automation to gain a competitive edge. By reducing manual work, improving accuracy, and enabling real-time insights, our solutions empower your teams to focus on strategic growth and customer satisfaction.

Choosing Bitcot means partnering with a company that is experienced, reliable, results-driven, and strategically aligned with your business goals. With Bitcot, your supply chain automation isn’t just about efficiency; it’s about transforming your operations into a smart, scalable, and future-ready system that drives growth, resilience, and long-term success.

Final Thoughts

Supply chain order management touches nearly every part of a business, and it’s easy for things to get tangled when processes rely heavily on manual effort.

Supply chain order management touches nearly every part of a business, and it’s easy for things to get tangled when processes rely heavily on manual effort.

Automating these workflows with Power Automate doesn’t just speed things up; it brings clarity, consistency, and confidence to the entire operation.

When orders flow smoothly, approvals happen without delays, and inventory aligns perfectly with demand, the team can focus on what really matters: building stronger relationships with suppliers, delivering a better experience to customers, and growing the business. It’s not just about efficiency; it’s about making work feel less stressful and more predictable.

Working with a partner like Bitcot ensures that automation is done thoughtfully, tailored to your unique challenges, and built to scale as your business grows. With our workflow automation services, the result is a supply chain that feels intelligent, responsive, and reliable, not just automated.

At the end of the day, automation isn’t a replacement for people; it’s a tool that empowers them to work smarter, reduce friction, and focus on meaningful work. That’s the real transformation a solution like this brings.

Get in touch with our team.