In mining and natural resources, work orders are the lifeblood of daily operations.

They make sure equipment gets maintained, resources are allocated efficiently, and everything from production to scheduling runs smoothly.

But here’s the catch: these work orders rarely stay in one place.

They move across multiple systems like ERP, asset management, supply chain, and scheduling tools. It’s easy for things to slip through the cracks, approvals to get delayed, and teams to spend more time chasing updates than actually getting work done.

That’s where automation steps in.

With Power Automate, you can connect all these systems and streamline how work orders are created, routed, and tracked, reducing manual effort, minimizing errors, and giving your team more time to focus on what really matters: keeping operations running safely and efficiently.

In this blog, we’ll explore exactly how mining and natural resources companies can harness Power Automate to simplify work order processing and keep their operations moving without the usual headaches.

Challenges in Traditional Work Order Processing

In the mining and natural resources sector, work orders aren’t just pieces of paper; they’re the backbone of daily operations. They ensure machinery is maintained, resources are allocated correctly, and operational tasks are completed on time.

Yet, despite their importance, many companies still rely on traditional, manual work order processes.

And that comes with a host of challenges:

1. Manual Data Entry Across Multiple Systems

In mining and natural resources, work orders rarely stay in a single system. Coordinators often have to enter the same information multiple times across ERP, asset management, and scheduling platforms. This repetitive task consumes hours that could be spent on actual operations or planning. The more systems a company uses, the more time is wasted copying and verifying details for each one.

Every re-entry increases the chance of mistakes, such as missing fields or incorrect equipment IDs. Over time, these small errors accumulate, slowing down workflows across departments. Teams spend more energy fixing mistakes than completing meaningful work.

This inefficiency can create frustration and lower morale across the organization.

2. Delayed Scheduling Due to Resource Availability Checks

Scheduling work orders in mining operations is rarely straightforward. Coordinators must confirm which technicians are available and whether the necessary equipment is free. They also need to check if materials or spare parts are on hand, often relying on emails, phone calls, or spreadsheets.

Any delay in confirming resources can push maintenance or operational tasks back by hours or even days. These delays make planning reactive rather than proactive, forcing teams to constantly adjust priorities. Supervisors struggle to coordinate multiple work orders simultaneously. The cumulative effect reduces overall productivity and can create bottlenecks.

Ultimately, delayed scheduling impacts efficiency, timelines, and operational goals.

3. High Error Rates When Re-Entering Work Order Details

Every manual data entry introduces the risk of errors in mining operations. Mistyped equipment IDs, missing task details, or misassigned technicians are common problems. Even small mistakes can cause missed maintenance, delays, or safety hazards. Field teams may arrive unprepared, without the right tools, instructions, or parts, further slowing down operations.

Correcting these errors consumes additional hours, energy, and resources that could be used elsewhere. Errors also affect reporting and compliance, adding administrative burdens.

Over time, high error rates lower operational efficiency, increase costs, and frustrate teams. Maintaining accuracy becomes a constant struggle without automated systems in place.

4. Limited Visibility into Work Order Status

Without centralized tracking, managers and field technicians struggle to see the real-time status of work orders. They often don’t know which tasks are completed, delayed, or pending approval, which leads to guesswork. This lack of visibility makes planning reactive instead of proactive, slowing overall operations.

Teams may duplicate work or miss critical steps entirely, creating inefficiencies. Managers spend significant time chasing updates instead of focusing on strategic priorities. Limited transparency can result in operational bottlenecks, slow response times, and missed deadlines. Field technicians also feel frustrated without clarity on priorities.

Poor visibility impacts productivity, coordination, and the smooth functioning of operations across the organization.

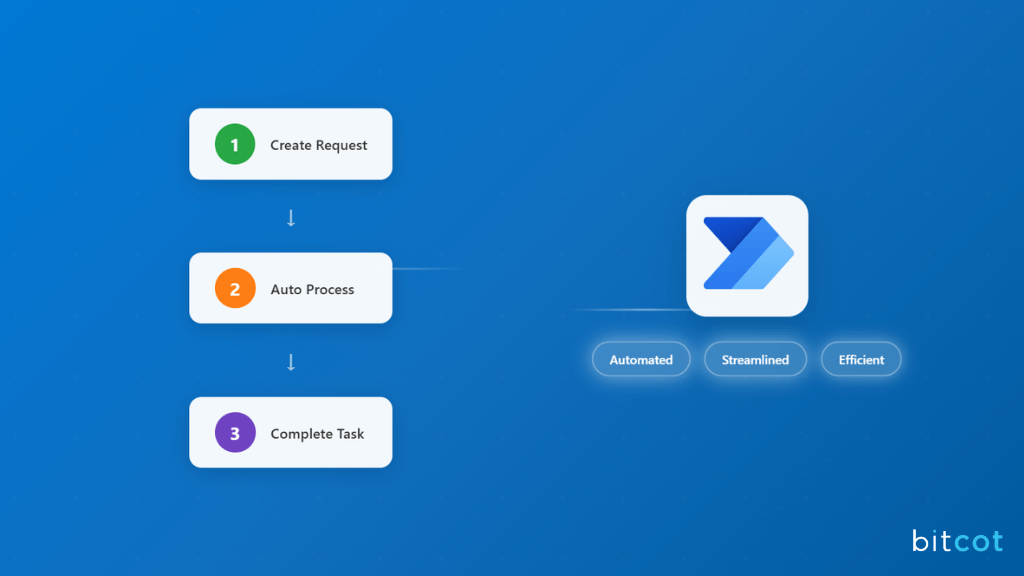

How Power Automate Transforms Work Order Processing

Work order processing may seem straightforward, but in reality, it often involves juggling multiple tasks. When handled manually, this process is prone to delays, errors, and miscommunication.

Power Automate transforms this process into a connected, efficient, and intelligent workflow.

By automating the repetitive steps and enabling real-time decision-making, it allows organizations to reduce administrative overhead and focus on completing work orders faster and more accurately.

Automating Work Order Intake from Multiple Channels

Work orders don’t come from just one source. They might arrive through:

- Field technician mobile applications

- Maintenance request portals

- Emails from staff or vendors

- Automated triggers from ERP systems

Manually consolidating these requests is time-consuming and increases the chance of oversight. With Power Automate, work order intake is seamless. Every request, regardless of where it originates, is automatically captured, logged, and routed to the right workflow.

This not only speeds up the intake process but also ensures no request is lost or delayed.

Real-Time Resource and Equipment Availability

One of the biggest challenges in work order management is making sure the right resources are available at the right time. A technician may be double-booked, or essential equipment may already be in use. Without automation, this often results in back-and-forth communication, wasted time, and rescheduling.

Power Automate removes this friction by connecting directly to resource and equipment databases. It validates incoming requests against real-time availability, checking that all required fields are completed and cross-referencing technician schedules or equipment status instantly. This proactive validation ensures accurate planning and reduces the chance of conflicts later in the process.

Smarter Scheduling When Conflicts Arise

Even with thorough planning, conflicts are sometimes unavoidable. A technician may be unavailable, or critical equipment may already be assigned elsewhere. In traditional workflows, this can stall the entire process while teams manually search for alternatives.

Power Automate streamlines conflict resolution by automatically generating alternative schedules. It can suggest different time slots, recommend other qualified technicians, or highlight backup equipment options. Managers can review these options quickly and approve the best fit, often directly within collaboration tools like Microsoft Teams.

This capability prevents small scheduling issues from turning into larger delays.

Parallel Updates Across ERP and Asset Management Systems

In most organizations, work orders touch multiple platforms. ERP systems handle financial or operational data, while asset management systems track maintenance and equipment usage. Updating both manually takes time and creates opportunities for inconsistencies.

Power Automate synchronizes these systems in parallel. Once a work order is confirmed, updates are pushed simultaneously to ERP and asset management systems such as SAP, Maximo, or Dataverse. This ensures data accuracy across all platforms, eliminates duplicate entry, and allows different teams to access the same up-to-date information.

Real-Time Status Tracking and Visibility

Assigning and scheduling a work order is only the beginning; monitoring execution is just as important. Without real-time visibility, managers often rely on manual updates or after-the-fact reporting, leaving them unaware of delays until it’s too late.

Power Automate provides live status tracking throughout the lifecycle of the work order. Technicians can update progress on the go, supervisors can monitor jobs in real time, and stakeholders can access dashboards with up-to-date information. This transparency reduces the need for constant check-ins, speeds up escalations when issues occur, and keeps everyone aligned on progress.

How to Automate Work Order Processing with Power Automate

Power Automate provides a structured way to automate work order processing, connecting multiple systems and teams while reducing manual effort.

By implementing the following seven steps, organizations can streamline work order processing, reduce manual errors, improve resource utilization, and gain real-time visibility across operations, all while saving time and improving overall efficiency.

Here’s a detailed breakdown of each step:

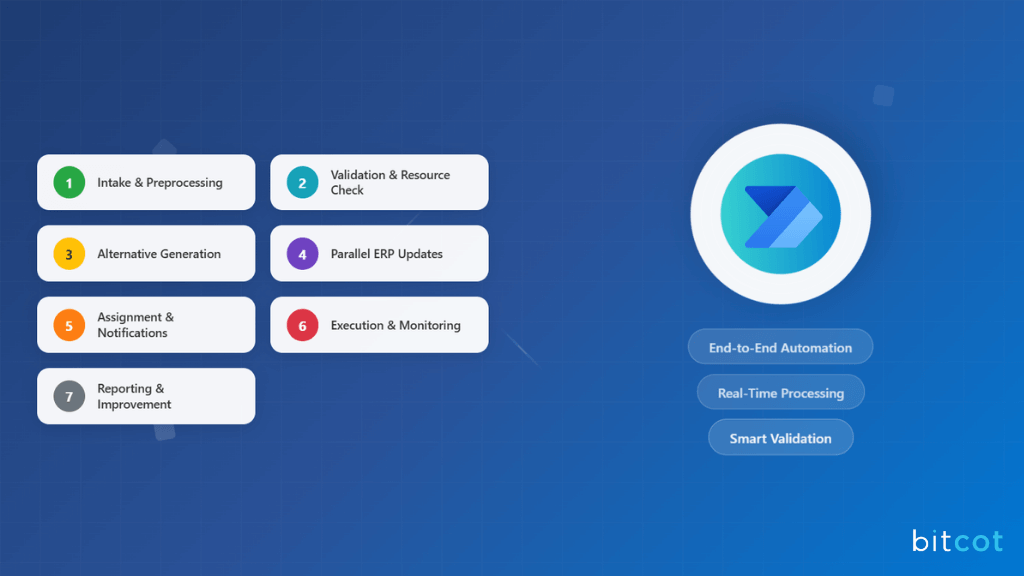

Step 1: Work Order Intake & Preprocessing

Work orders can come from multiple channels, making manual intake tedious and error-prone:

- Field technician mobile apps: Technicians submit on-site requests or updates directly.

- Maintenance request portals: Internal or external portals generate work orders automatically.

- Email submissions: Requests can arrive from customers or internal staff.

- ERP system triggers: Some work orders originate from ERP events or automated business rules.

Power Automate Actions

- When a new item is created: Automatically captures requests from SharePoint or Dataverse, ensuring no work order is missed.

- When a new email arrives (V3): Extracts work order requests from email content, eliminating manual reading and entry.

- Get file content: Pulls details from attached PDFs or Excel sheets, standardizing data input.

- AI Builder document extraction: Parses structured and unstructured forms to automatically extract relevant fields like asset ID, job type, location, and requester.

This step ensures that all incoming work orders are captured, organized, and ready for processing without manual intervention.

Step 2: Validation & Resource Availability Check

Before assigning work, it’s essential to validate the request and check if the required resources are available.

Power Automate Actions

- Condition: Confirms that mandatory fields (asset ID, job type, requester) are filled. Missing information is flagged automatically.

- SQL Server – Get rows: Queries the resource and equipment database to check availability in real-time.

- Filter array: Identifies resources that match the work order requirements, such as technicians with the right skills or available machines.

- Compose: Generates a summary of available resources, helping managers make quick decisions.

Automating validation prevents incomplete work orders from moving forward and ensures resources are properly allocated.

Step 3: Alternative Generation (if conflicts)

Sometimes, requested resources are unavailable, which could delay the work order. Power Automate generates alternatives automatically:

Power Automate Actions

- Switch: Handles different scenarios, such as resource available versus unavailable.

- Select: Suggests alternative resources, dates, or schedules.

- Post adaptive cards and wait for a response: Sends options to supervisors via Teams, allowing them to approve alternatives without leaving their workflow.

This reduces scheduling conflicts and ensures work orders continue moving even when resources are constrained.

Step 4: Parallel Updates in ERP & Asset Systems

Once a work order is confirmed, it often needs updates in multiple systems simultaneously:

Power Automate Actions

- HTTP: Pushes updates to the ERP system with work order details.

- Update record: Synchronizes asset management systems (Dataverse, Maximo, SAP) in real-time.

- Scope: Runs updates in parallel branches, improving speed and efficiency.

This step prevents duplicate data entry, ensures system consistency, and saves time for the operations team.

Step 5: Work Order Assignment & Notifications

Assigning tasks and notifying stakeholders is a critical step to ensure accountability and timely execution.

Power Automate Actions

- Create item: Assigns the work order to the appropriate technician in SharePoint or Dataverse.

- Send push notification: Alerts technicians immediately on mobile devices.

- Post a message in Teams: Updates the operations team on the new assignment or schedule.

- Send an email (V2): Provides work order details to managers or other stakeholders.

Automation ensures the right people are informed immediately, reducing delays and miscommunication.

Step 6: Execution & Monitoring

During execution, real-time tracking ensures work is progressing as planned and exceptions are handled promptly.

Power Automate Actions

- Update item: Logs technician status (in progress, completed, delayed) to keep records current.

- Append to string variable: Tracks progress logs for auditing and reporting purposes.

- Condition: Detects delays or exceptions and triggers escalations automatically.

Monitoring through automation enables faster response to issues and maintains accountability throughout the process.

Step 7: Reporting & Continuous Improvement

Automating reporting allows teams to analyze performance, identify bottlenecks, and improve workflows.

Power Automate Actions

- Add a row into a table: Stores completed work orders in Excel or Dataverse for record-keeping.

- Refresh a dataset: Updates Power BI dashboards in real-time for operational insights.

- Create an HTML table: Generates weekly or monthly reports for leadership review.

This final step provides actionable insights, supports continuous process improvement, and ensures transparency at every level.

Benefits of Automating Work Order Processing with Power Automate

Implementing Power Automate for work order processing delivers tangible benefits across operations, resources, and decision-making.

By automating routine tasks, organizations can achieve faster turnaround, higher accuracy, and better overall performance.

Faster Work Order Turnaround

Manual intake, validation, and assignment of work orders can create delays, especially when requests come from multiple channels.

Power Automate accelerates every step of the process:

- Incoming requests are captured automatically from mobile apps, portals, emails, or ERP triggers.

- Validation checks and resource assignments are processed in real-time.

- Supervisors can approve alternatives or adjustments instantly through adaptive cards in Teams.

The result is a significant reduction in the time it takes to move work orders from submission to completion, ensuring faster service delivery and more satisfied stakeholders.

Improved Resource Utilization

Inefficient scheduling or unavailable resources often cause work order delays.

Power Automate optimizes resource usage by:

- Checking technician availability, skills, and equipment in real time.

- Matching work orders to the right personnel and assets based on current workloads.

- Proposing alternatives automatically when conflicts arise, reducing idle time and preventing overbooking.

This ensures that resources are used efficiently, minimizing downtime and maximizing operational capacity.

Higher Accuracy

Manual entry and updates across multiple systems introduce the risk of errors.

With Power Automate:

- Work order information is automatically updated in ERP and asset management systems simultaneously.

- Validation rules ensure that all required fields are complete before processing.

- AI-driven document extraction reduces errors from manually typed data.

Automated updates and validation significantly reduce mistakes, improving data integrity and ensuring that all teams work with consistent, reliable information.

Increased Technician Productivity

Technicians often lose time checking schedules, tracking assignments, or searching for updates.

Power Automate empowers technicians with instant access to work order information:

- Mobile notifications alert technicians immediately when a task is assigned or updated.

- Technicians can receive real-time updates on equipment availability or scheduling changes.

- Simplified workflows free technicians from administrative tasks, allowing them to focus on completing work efficiently.

This results in higher productivity, faster job completion, and a more satisfied workforce.

Better Decision-Making

For operations managers and leadership, having visibility into work order performance is critical.

Power Automate integrates seamlessly with Power BI dashboards to provide actionable insights:

- Real-time reporting highlights bottlenecks, delayed tasks, and workload distribution.

- Historical trends help identify recurring issues or resource constraints.

- Data-driven insights support strategic planning, resource allocation, and continuous process improvement.

Decision-makers can act quickly and confidently, improving operational efficiency and long-term performance.

Future Enhancements in Work Order Processing Automation

As organizations continue to embrace digital transformation, work order processing can evolve beyond basic automation into a smart, predictive, and highly efficient system.

Emerging technologies and advanced tools offer opportunities to further enhance operations, resource management, and decision-making.

Here are some key future enhancements:

IoT-Driven Predictive Maintenance

Integrating IoT sensors with work order automation enables predictive maintenance:

- Sensors on machines and equipment can monitor real-time performance and detect anomalies.

- Power Automate can automatically generate work orders when sensors indicate potential issues, preventing costly downtime.

- Predictive alerts allow teams to schedule maintenance proactively rather than reactively.

This approach reduces unexpected equipment failures, optimizes maintenance schedules, and extends asset lifespan.

AI-Driven Resource Optimization

Artificial intelligence can take resource allocation to the next level:

- AI algorithms can analyze historical work order data, technician performance, and equipment usage patterns.

- Power Automate can use these insights to automatically assign the most suitable resources to each work order.

- The system can balance workloads dynamically, reducing idle time and minimizing conflicts.

AI-driven optimization ensures that every work order is completed efficiently while maximizing resource utilization.

Chatbot-Assisted Approvals and Reassignments

Supervisors often spend significant time approving, reassigning, or modifying work orders. AI-powered chatbot assistants can streamline these tasks:

- Supervisors can approve or reassign work orders using chatbots in Teams or other collaboration platforms.

- Chatbots can provide summaries, highlight conflicts, and suggest alternatives.

- Immediate feedback accelerates workflow and reduces delays caused by manual approvals.

This makes supervision faster, more responsive, and less reliant on email or manual tracking.

Automated Work Order Invoicing and Cost Allocation

Linking work order automation to finance systems brings financial transparency and efficiency:

- Completed work orders can automatically trigger invoicing processes.

- Labor, equipment usage, and material costs can be allocated to projects or departments automatically.

- Integration with ERP or accounting systems ensures accurate, real-time financial reporting.

Automation in invoicing and cost allocation reduces administrative effort, minimizes errors, and improves financial visibility.

Partner with Bitcot to Automate Work Order Processing with a Custom Solution

Streamlining work order processing is not a one-size-fits-all task. Every organization has unique workflows, systems, and operational challenges.

That’s where Bitcot comes in, delivering custom Power Platform solutions tailored to your business needs.

Why Choose Bitcot?

- Expertise in Automation Solutions: Bitcot’s team specializes in designing and implementing automation workflows using Power Automate. From intake to monitoring, we ensure every step of your work order process is optimized for speed, accuracy, and efficiency.

- Tailored Workflows for Your Organization: Off-the-shelf automation often falls short for complex operational environments. Bitcot develops custom workflows that integrate seamlessly with your existing ERP, asset management systems, CRM platforms, and collaboration tools.

- Enhanced Productivity and Resource Management: With Bitcot’s Power Platform solution, your teams receive:

- Automated task assignments and notifications

- Real-time resource availability checks

- Intelligent scheduling to prevent conflicts

- Live status updates for better operational visibility

- Scalable and Future-Ready Automation: Bitcot designs solutions that not only solve today’s challenges but are ready for future enhancements: IoT-driven predictive maintenance, AI-powered resource optimization, chatbot approvals, and automated invoicing.

How Bitcot Works With You

- Assessment: Analyze your current work order processes and identify bottlenecks.

- Design: Develop a custom Power Automate workflow that fits your operational needs.

- Implementation: Integrate workflows across your systems with minimal disruption.

- Support & Optimization: Monitor performance, make enhancements, and scale the solution as your business grows.

Partnering with Bitcot ensures that your organization not only automates work order processing but transforms it into a smart, efficient, and future-ready operation.

By combining deep domain expertise with Power Automate capabilities, Bitcot empowers businesses to reduce costs, improve productivity, and achieve operational excellence.

Final Thoughts

Automating work order processing is no longer just a technological upgrade; it’s a strategic advantage.

By leveraging Power Automate, organizations can streamline intake, validate and allocate resources efficiently, manage conflicts in real-time, synchronize multiple systems, and gain actionable insights through reporting dashboards. The result is faster turnaround times, higher accuracy, improved resource utilization, and a more productive workforce.

Looking ahead, integrating emerging technologies like IoT-driven predictive maintenance, AI-powered resource optimization, and chatbot-assisted approvals will further elevate operational efficiency, making work order management smarter, more proactive, and highly adaptive to changing business needs.

For organizations seeking to unlock the full potential of workflow automation services, partnering with an expert like Bitcot ensures a tailored solution that fits your unique operational requirements. From custom Power Automate workflows to seamless system integration, Bitcot helps businesses reduce costs, enhance productivity, and achieve operational excellence.

Ready to transform your work order processes?

Contact Bitcot today to explore a custom automation solution designed to streamline your operations and drive measurable results.